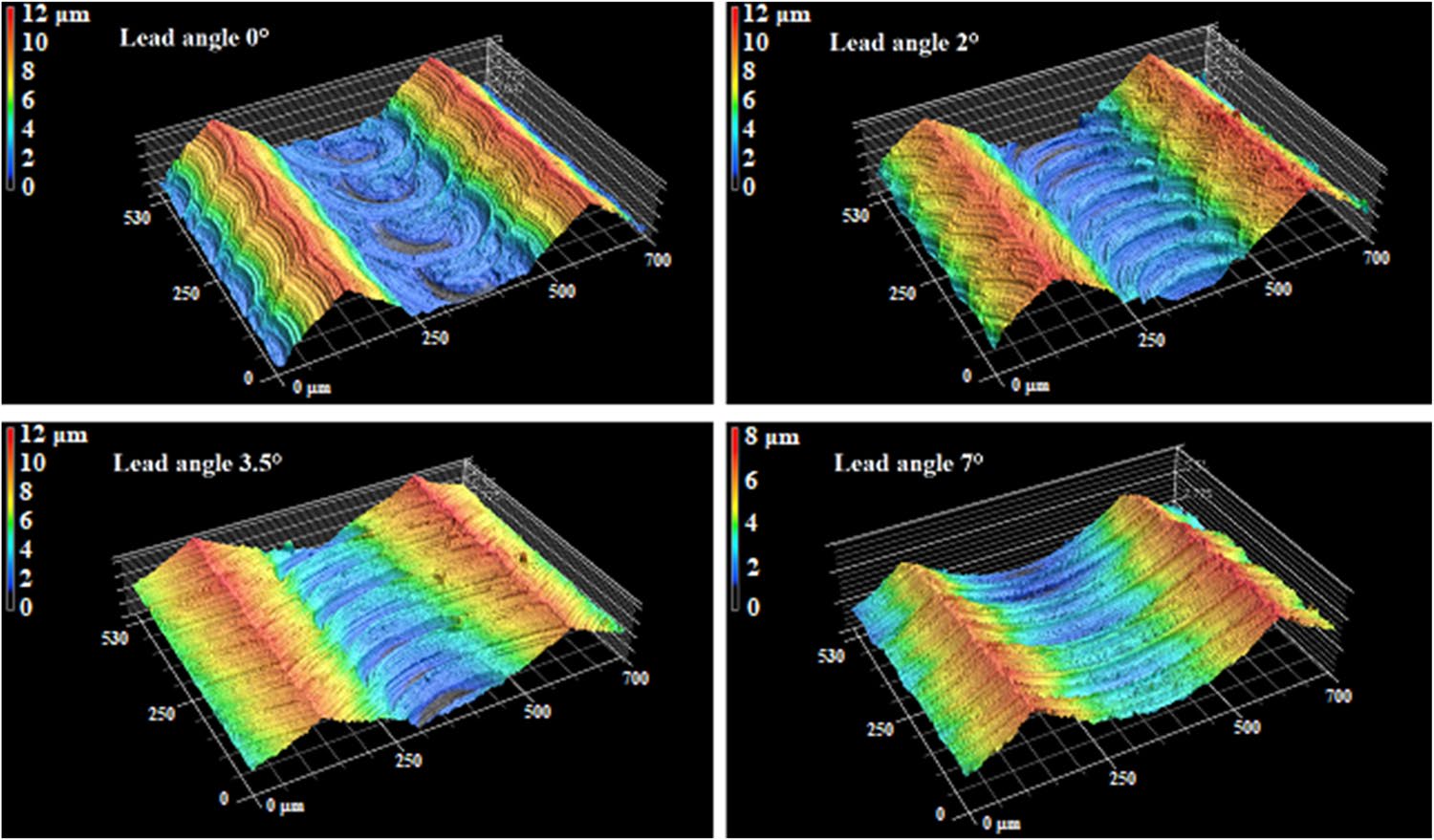

When milling generally shaped surfaces with a ball-end milling tool, machined surface roughness and accuracy as well as machining productivity are often monitored. Improving one of these parameters often causes a decrease in the other monitored parameters. Therefore, knowing possible ways of influencing these parameters is important for achieving the optimum result, if possible, in all requirements. A deep understanding of how some technological parameters influence finished surface roughness is still lacking, as well as detailed knowledge of the relationships among some roughness parameters. In response, an experiment entailing machining of planar samples at different orientation angles was carried out to identify the influence of the studied parameters on the transverse roughness of the final surface. A finding was made that the resulting surface roughness is dependent on the cutting edge geometry of the particular ball-end milling tools used, and the achieving of the required surface roughness can be guaranteed by setting the specific lead angles. Furthermore, it was verified that a minimum lead angle limit can be found based on the geometric properties of the specific milling tool, and the relationship between the evaluated roughness parameters Ra and Rz was found as well.