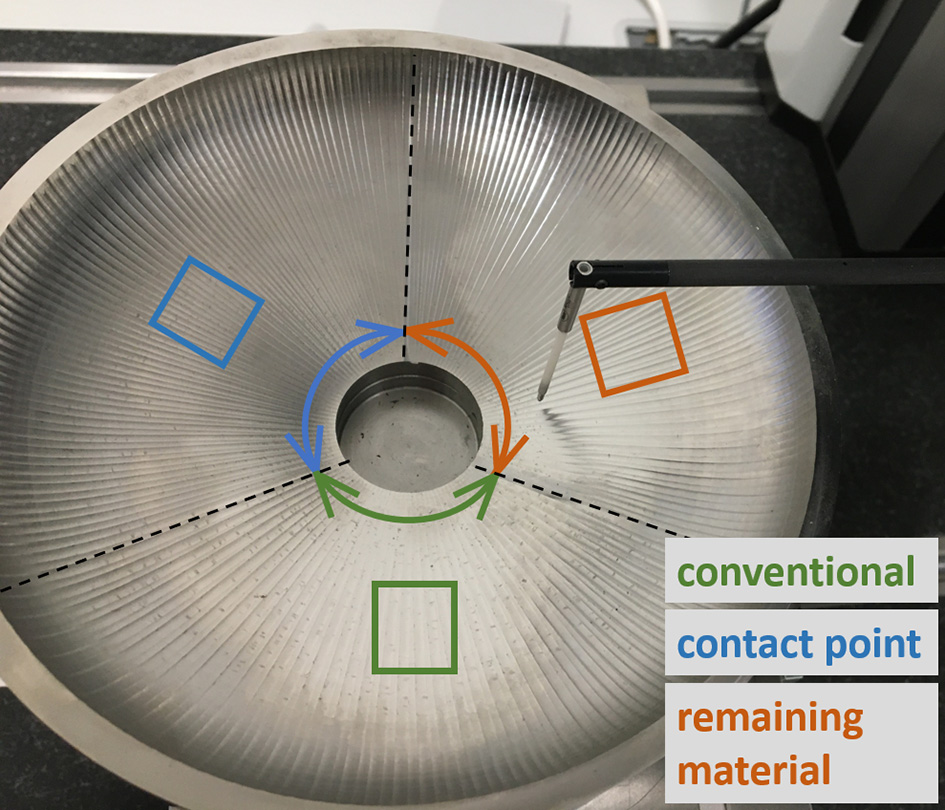

This paper focuses on dynamic spindle speed and feed rate control to increase tool life and reduce machining time during milling of complex shaped parts. Machining of complex shaped surfaces is one of the most demanding machining applications, especially if the workpiece is made of difficult-to-cut material. Tool life needs to be considered during selection of cutting conditions. Both feed rate and cutting speed also have a direct effect on the resulting roughness and accuracy. When machining with tools with a circular cutting edge, such as ball or toroidal mills, the real cutting diameter of the tool changes continuously and as a result the cutting speed along the toolpath also changes continuously. Therefore a new method to compute the required spindle speed and feed rate was proposed based on the implemented kinematic parameters of a real spindle controller. In addition, a method to calculate the effective cutting radius of the tool based on the actual height of the remaining material was proposed to achieve a constant cutting speed through dynamic spindle speed control. The benefits of using the new optimization method were verified when machining a duplex stainless steel (1.4462) part. This test confirmed that the new optimization method results in a significant increase in tool life as well as a sig-nificant saving of machining time, while achieving the desired surface quality.